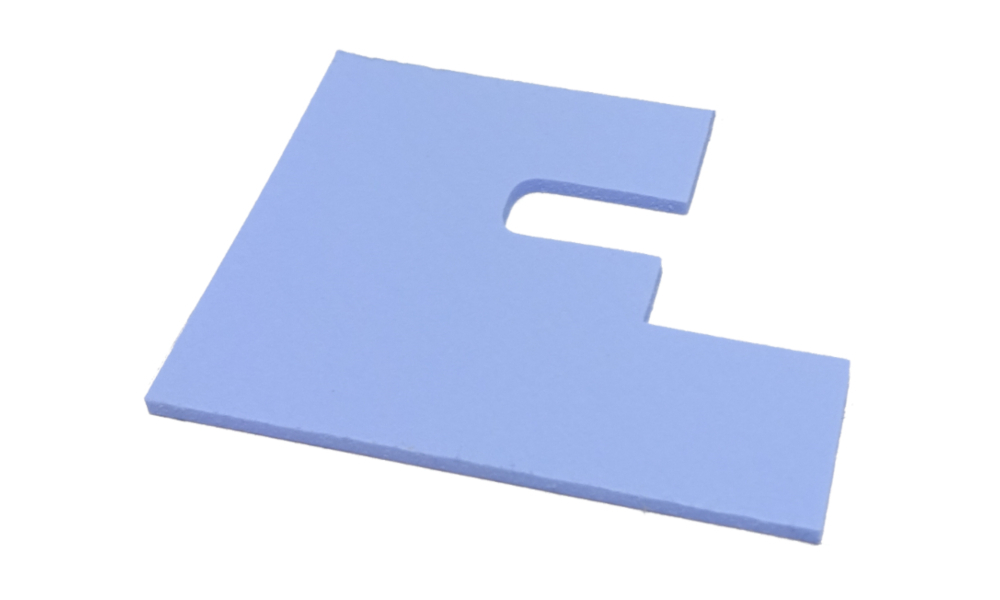

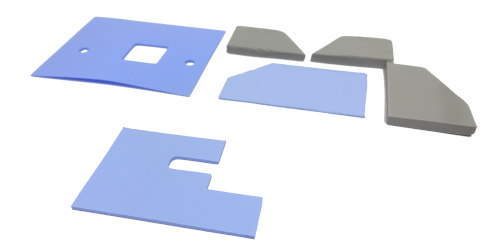

Optimal thermal management is critical to maintaining the performance, longevity and reliability of electronic components. Thermal pads, often made of silicone or similar materials, play an important role in dissipating heat between various components and heat sinks. Although thermal pads usually come in standard sizes, there are cases where these pads need to be cut precisely (or produced in a custom shape with a mold) to fit properly. In this article, we will explore the scenarios where special cutting or custom shape molding of thermal pads becomes necessary.

1. Unique Component Arrangement:

In certain electronic devices, such as custom circuit boards, graphics cards, or computer cooling systems, the spacing and arrangement of components may differ from the standard. In such cases, standard thermal pads may not fit the complicated arrangement. Special cutting of the thermal pads is required to ensure an exact fit between the components and the heat sinks and to enable efficient heat transfer.

2. Irregularly Shaped Electronics:

Technological advances have led to the creation of increasingly compact and uniquely shaped electronic devices. In these cases, the heat dissipation modules, such as heat pipes or custom cooling solutions, often have unconventional shapes and dimensions. Cutting thermal pads to fit these unconventional shapes ensures proper thermal contact and efficient heat transfer, ultimately improving the overall performance of the device.

3. Repair or Replacement:

When repairing or replacing components, it is not uncommon for the size of the original thermal pad not to match that of the replacement. In such cases, special cutting of the thermal pads can help maintain the thermal integrity of the repaired or replaced components. Precise cutting of the pads can reduce the risk of inadequate heat dissipation or damage to the electronic hardware.

4. Custom-built Computers:

Custom-built computers that have been assembled in a deviant manner often require special cuts of thermal pads to ensure the best fit of the heatsink to the selected CPU or GPU models. By adjusting the size and shape of the thermal pads, they can provide better thermal performance and overclocking potential.

Our wide range of die-cutting and custom shape molding services for thermal pads give you the opportunity to get exactly the product that meets your individual needs. Contact us for a free consultation and / or a quotation.